We develop innovative precision technological solutions with passion and expertise to ensure that everyday devices and objects work perfectly, and we do so with respect for the environment and human values.

The expertise and experience gained in over 70 years of activity allows us to support our customers right from the design stage, advising and assessing the best technical solutions together to create complex products with high quality features. Constant research, specialist expertise and continuous investment in technology have ensured that our company has grown steadily over the years.

Sustainability

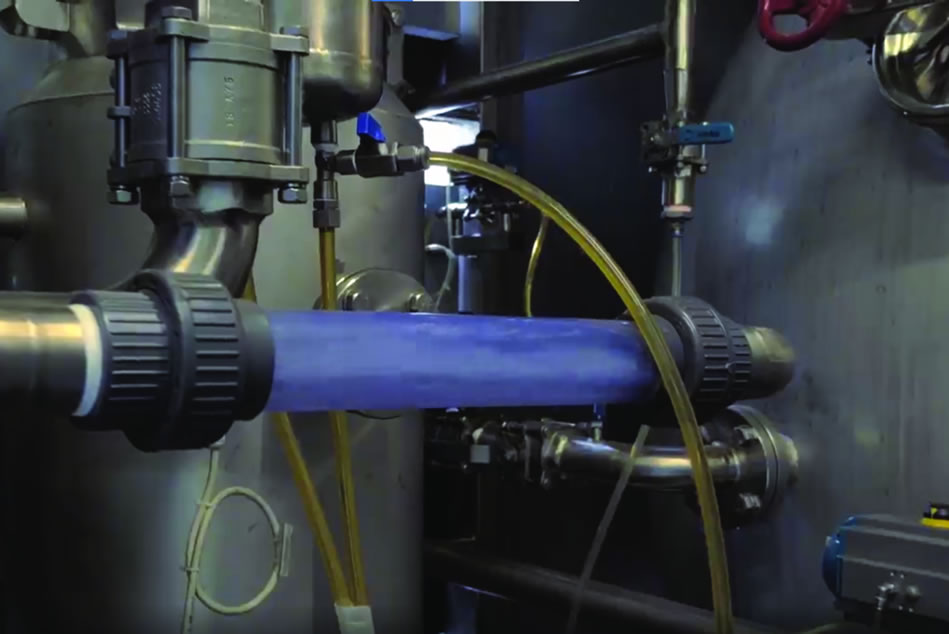

In 2019, we built a tri-generator at the Cisano Bergamasco site, specifically designed for our facilities and needs. This system allows us to produce our own electricity, which meets more than two thirds of the company's needs. In addition, the thermal energy released by the cogenerator is used entirely at our site, to heat and cool our offices, for production purposes and to run a water purifier.

We have a water purifier connected to the tri-generator to protect the environment by reducing the volume of process waste by 98.5%. In line with the circular economy philosophy, the evaporated water is in fact used to operate the system.

The purifier means we can reuse 700,000 litres/month of waste water, thus reducing fresh water consumption and avoiding discharge into the public sewers. A significant economic, environmental and health benefit that allows us to conserve fresh groundwater, the most precious resource for the entire planet.

Digita is a project designed in-house at M.S.Ambrogio, with the aim of drastically reducing paper and energy consumption in production departments by digitising all paper documentation in use.

This project led us to equip all production departments with more than 100 tablets. Our operators will be able to use them to check technical documentation and interact with the SAP system, thereby significantly improving document management and conserving the environment.

We conducted an analysis of greenhouse gas emissions for the Cisano Bergamasco and Chignolo d'Isola plants. The analysis gave very satisfactory results regarding M.S.Ambrogio's low contribution to direct emissions, only 8% of the total value. This remarkable performance was mainly attributed to the choice of purchasing raw materials from suppliers located in Italy (67%) and neighbouring countries. However, the most significant reduction opportunity lies in the supply chain itself, which currently accounts for 84% of M.S.Ambrogio's greenhouse gas emissions and on which we have focused in order to plan effective strategies to reduce our company's climate impact.

Training

For us, progress is progress when it involves everyone.

Since 2015, we have been running an in-house Academy with the collaboration of renowned local professional institutes, the Politecnico di Milano and Adecco, to provide young graduates with technical training in the field of mechatronics.

The 6-month study course comprises a first phase of theoretical learning with qualified specialists and lecturers, and a second phase of practical learning in the various departments. The study course includes a daily expense allowance for attending students and is aimed at placement in the company.

Social Responsibility

Our sustainable development policy also includes actions to benefit the corporate community and local communities. Over the years, M.S.Ambrogio has promoted corporate welfare projects and supported important initiatives to disseminate entrepreneurial culture, art, sport and education.

Our Initiatives

The “Cinzia Sangalli” Scholarship

Every year since 2013, the Sangalli family has come together to award workers’ children with a scholarship for scholastic merit. The initiative is aimed at supporting and encouraging young people to pursue their goals and deepen their knowledge and skills, in order to ensure a future of growth and development for themselves and for the entire community.